Industry drives international development and progress

Specialized Metal Fabrication Solutions

Experience and Technology Evolving Since 2016

With a commitment to quality, cutting-edge technology, and a specialized team, we create customized solutions that enhance our clients' products and drive technological advancements.

After more than two decades of gaining practical experience and deep understanding of the industry, the company was founded in 2016, focused on precision machining, investing in state-of-the-art machinery and building a specialized team.

The success of our customers, providing tailored precision solutions. Our mission is to deliver superior quality with consistency and speed.

Quality and efficiency through a simple, customer-centric approach that prioritizes client needs.

After more than two decades of gaining practical experience and deep understanding of the industry, the company was founded in 2016, focused on precision machining, investing in state-of-the-art machinery and building a specialized team.

The success of our customers, providing tailored precision solutions. Our mission is to deliver superior quality with consistency and speed.

Quality and efficiency through a simple, customer-centric approach that prioritizes client needs.

Our journey began when the company’s founder, at just 15 years old, took his first steps in machining. For over ten years, he worked on machine repairs, acquiring the foundation of technical knowledge that characterizes our company today. This period taught him to tackle complex technical problems and work with precision.

In 2016, the accumulated experience led to the creation of an independent machine shop. Instead of limiting ourselves to repairs, we expanded our activities to custom mechanical engineering fabrications for general use. Our approach was to offer personalized solutions for each client, which gradually built a stable customer base.

That same year, Savvas Mech was officially established as a sole proprietorship. We started with a conventional lathe and milling machine – traditional equipment that allowed us to perform high-quality, precision work.

In 2020, we took our first major step toward modern technology with the addition of three CNC milling machines M1. This transition from conventional machines to CNC technology allowed us to significantly expand our capabilities. The precision of automated control and the ability to produce complex shapes opened up new possibilities in the services we offer.

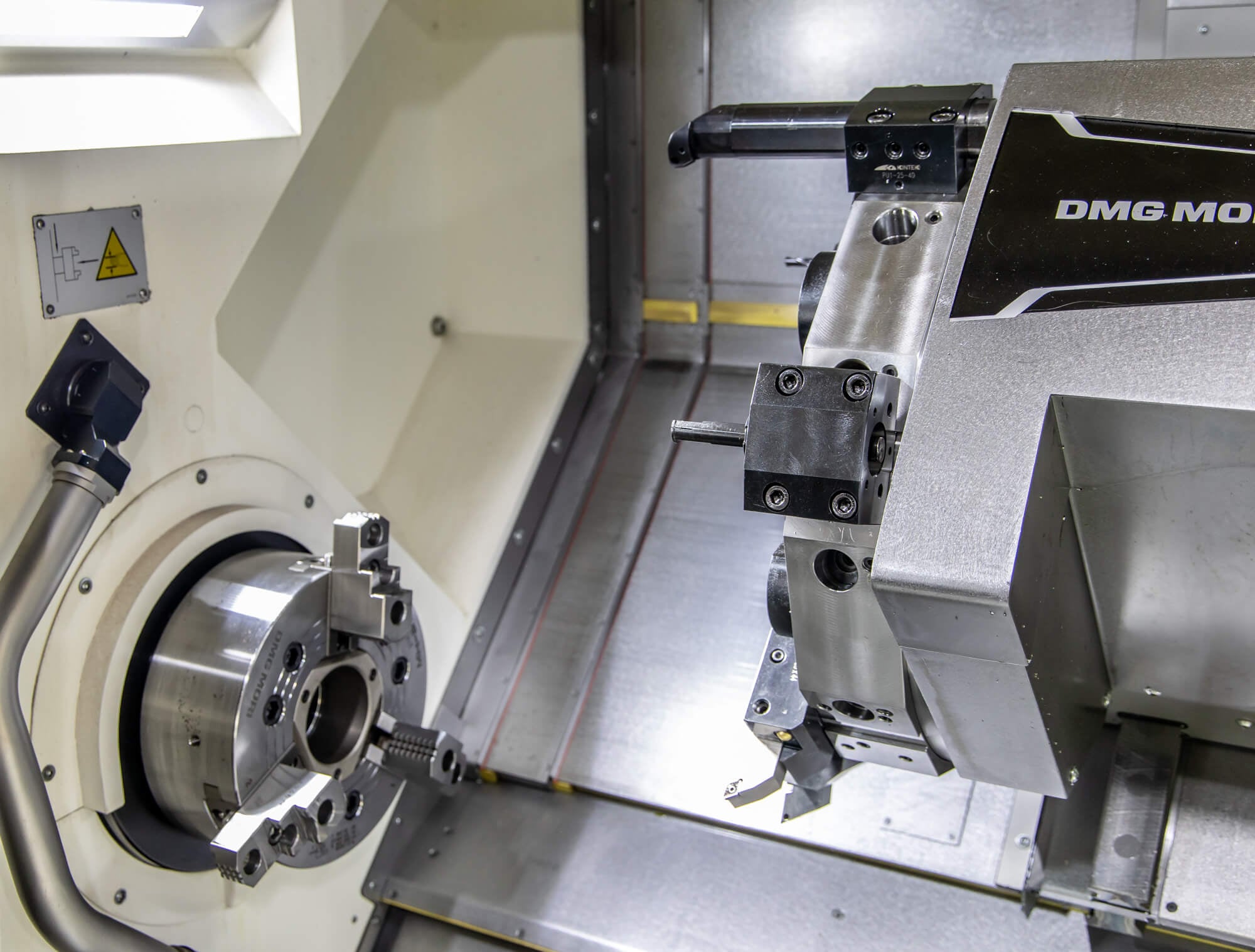

The installation of the 5-axis CNC lathe CLX 450 V in 2022 represented a significant addition to our equipment. This type of machine gives us the ability to perform complex operations with a single setup, reducing production times and increasing accuracy. This enables us to undertake projects that require a higher level of technical expertise.

In 2023, we added the M2 (OE) machine to our equipment, further increasing our production capacity. Simultaneously, our successful participation in major tenders confirmed our technical capability and reliability as a partner.

We anticipate certification from the relevant regulatory body, which will represent formal acknowledgment of the quality standards we have implemented. We have secured a well-established market position founded on the reliable quality of our services and our customers’ confidence.

Our next steps include adding new state-of-the-art machines to remain competitive in a continuously evolving industry. Simultaneously, we plan to strengthen our workforce with specialized personnel, recognizing that the right skills are essential for leveraging technology.

Our journey began when the company’s founder, at just 15 years old, took his first steps in machining. For over ten years, he worked on machine repairs, acquiring the foundation of technical knowledge that characterizes our company today. This period taught him to tackle complex technical problems and work with precision.

In 2016, the accumulated experience led to the creation of an independent machine shop. Instead of limiting ourselves to repairs, we expanded our activities to custom mechanical engineering fabrications for general use. Our approach was to offer personalized solutions for each client, which gradually built a stable customer base.

That same year, Savvas Mech was officially established as a sole proprietorship. We started with a conventional lathe and milling machine – traditional equipment that allowed us to perform high-quality, precision work.

In 2020, we took our first major step toward modern technology with the addition of three CNC milling machines M1. This transition from conventional machines to CNC technology allowed us to significantly expand our capabilities. The precision of automated control and the ability to produce complex shapes opened up new possibilities in the services we offer.

The installation of the 5-axis CNC lathe CLX 450 V in 2022 represented a significant addition to our equipment. This type of machine gives us the ability to perform complex operations with a single setup, reducing production times and increasing accuracy. This enables us to undertake projects that require a higher level of technical expertise.

In 2023, we added the M2 (OE) machine to our equipment, further increasing our production capacity. Simultaneously, our successful participation in major tenders confirmed our technical capability and reliability as a partner.

We anticipate certification from the relevant regulatory body, which will represent formal acknowledgment of the quality standards we have implemented. We have secured a well-established market position founded on the reliable quality of our services and our customers’ confidence.

Our next steps include adding new state-of-the-art machines to remain competitive in a continuously evolving industry. Simultaneously, we plan to strengthen our workforce with specialized personnel, recognizing that the right skills are essential for leveraging technology.

Our workshop is equipped with conventional lathes, milling machines and specialized machinery that enable us to execute high-precision projects. With years of experience and advanced technology, we cover every metalworking need for various industrial sectors.

Using cutting-edge equipment and expert staff, we deliver complete solutions for any metalworking challenge, catering to customers across all industry sectors.

We design and manufacture precision components for industrial applications, based on your specifications. Our experience covers everything from small parts to complex systems for use in demanding environments.

We operate state-of-the-art 3-axis CNC machines for metal processing with precision lower than 0.01 mm. We handle turning, milling, and drilling on every type of metal, from simple steel to specialized aluminum and titanium alloys.

We specialize in reproducing hard-to-find or uneconomical spare parts. We can accurately replicate existing components and create faithful copies, often improving upon the original design.

We collaborate closely with you from concept to completion, providing technical consultation for manufacturing optimization.

We possess the expertise and equipment for processing specialized materials such as stainless steel, titanium, and other high-performance alloys. We successfully handle the challenges presented by difficult-to-machine materials, ensuring excellent results.

We are ready to undertake your next project and implement it with precision and professionalism. Contact us to discuss your needs.

Karamanli Avenue 8, 19300, Aspropyrgos, Attica

Mon - Fri: 09:00 - 17:00 Sat: 09:00 - 14:30

Contact us for more information about our services.